Tesla Model 3: Halfshaft - Rear Drive Unit - LH - Install

Install

.jpg)

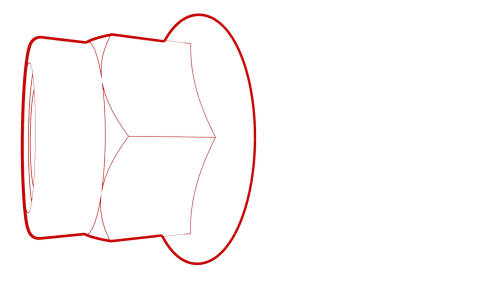

- Apply approximately 1 gram of Molykote M-77 Lubricant Paste only to the hub mating face on the outboard side of the LH rear drive unit halfshaft.

Caution: Do not apply any lubricant to the halfshaft splines. If lubricant is mistakenly applied, wipe the splines clean with a shop towel.

- Remove the halfshaft plug from the gearbox, and then install the halfshaft into the rear drive unit.

- Swing out the upper section of the knuckle and mate the halfshaft to the hub.

- Use the support stand to raise the LH rear suspension.

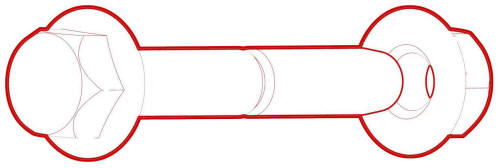

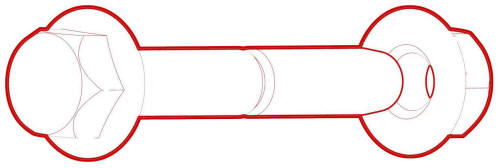

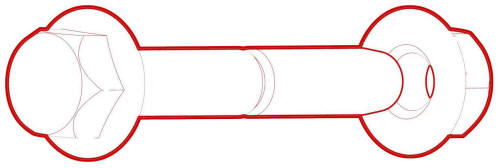

- Install the washer, and install and hand-tighten a new nut to attach the halfshaft to the LH rear hub.

- With an assistant, install and hand-tighten the bolt and nut that attach the LH toe link to the knuckle.

- With an assistant, installl and hand-tighten the bolt and nut that attach the LH upper fore link to the knuckle.

- With an assistant, install and hand-tighten the bolt and nut that attach the LH upper aft link to the knuckle.

- Install a new nut to attach the rear stabilizer bar

link to the rear stabilizer bar, and then mark the nut

with a paint pen.

Torque 55 Nm

Torque 55 Nm

Note: Counter-hold the ball joint with a 5 mm hex wrench.

.jpg)

- Install the bolts that attach the LH rear damper at the top mount. Torque 41 Nm

.png)

- Raise the support stand to simulate vehicle at ride height.

Note: Make sure that the support stand do not block access to adjust the spring compressor or suspension bolts.

Note: Use the rear ride height torque gauge to verify that the rear suspension is set to ride height specifications and adjust the support stand or spring compressor tool , if necessary.

.jpg)

- Measure the distance between the bottom of the quarter panel to the center of the rear axle to make sure that the rear suspension is set to ride height: The distance should measure 378 mm.

- Tighten the bolt and nut that attach the LH toe link

to the knuckle, and then mark the bolt and nut with a

paint pen.

Torque 76 Nm

Torque 76 Nm

- Tighten the bolt and nut that attach the LH upper

fore link to the knuckle.

Torque 76 Nm

Torque 76 Nm

- Tighten the bolt and nut that attach the LH upper

aft link to the knuckle, and then mark the bolt and nut

with a paint pen.

Torque 134 Nm

Torque 134 Nm

- Remove the support stand from underneath the LH rear suspension.

.png)

- Remove the spring compressor from the LH coil spring.

.jpg)

- Install the LH rear suspension cover to the lower aft link, and then install the bolt that attaches the suspension cover to the link. Torque 6 Nm

- Hand-tighten the LH axle nut again.

.jpg)

- Install the rear LH ABS wheel speed sensor to the LH

rear knuckle, and then install a new bolt to secure the

sensor to the knuckle.

.jpg) Torque 5 Nm

Torque 5 Nm

.jpg)

- Install the grommet and fasten the clip that attach the rear LH ABS wheel speed sensor cable to the rear LH knuckle and subframe bracket.

.png)

- Install the bolts that attach the LH rear caliper

bracket to the knuckle.

.jpg) Torque 80 Nm

Torque 80 Nm

- Install the bolt that attaches the electrical harness bracket to the LH rear brake caliper. Torque 5 Nm

.jpg)

- Connect the electrical harness to the LH rear brake caliper connector.

- Install the LH rear wheel arch liner. See Wheel Arch Liner - Rear - LH (Remove and Replace).

- Install the LH rear wheel, and then hand-tighten the lug nuts that attach the LH rear wheel to the hub.

- Lower the vehicle and put the vehicle into Park.

.jpg)

- Tighten the LH rear axle nut. Torque 245 Nm

- Tighten the wheel lug nuts. Torque 175 Nm

- Install the LH rear wheel center cap or the hub cap.

- Remove the vehicle from the lift.

- Perform the four wheel alignment check. See Four Wheel Alignment (Check).